Products

- Titanium Tablet

- Carbide Powder

- Nitride Powders

- Hydride Powders

- Silicide Powders

- Ti5Si3 Titanium Silicide

- TaSi2 Tantalum Silicide

- VSi2 Vanadium Silicide

- CrSi2 Chromium Silicide

- HfSi2 Hafnium Silicide

- Mg2Si Magnesium Silicide

- MnSi Manganese Silicide

- MoSi2 Molybdenum Silicide

- NbSi2 Niobium Silicide

- Ni2Si Nickel Silicide

- TiSi2 Titanium Disilicide

- WSi2 Tungsten Silicide

- FeSi2 Ferro Silicide

- ZrSi2 Zirconium Silicide

- Cu5Si Copper Silicide

- CoSi2 Cobalt Silicide

- Yttrium Disilicide,YSi2

- Calcium Silicide,CaSi2

- Boride Powders

- TiB2 Titanium Boride Powder

- TaB2 Tantalum Boride powder

- ZrB2 Zirconium Boride Powder

- VB2 Vanadium Boride Powder

- CaB6 Calcium Boride Powder

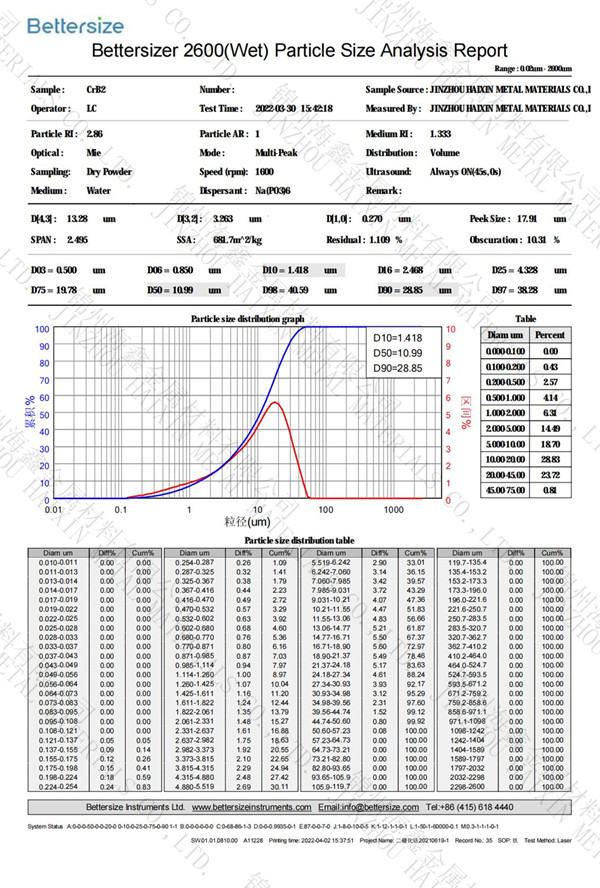

- CrB2 Chromium Boride Powder

- CoB Cobalt Boride Powder

- SiB6 Silicon Boride Powder

- HfB2 Hafnium Boride Powder

- AlB2 Aluminum Boride Powder

- MgB2 Magnesium Boride Powder

- MnB2 Manganese Boride Powder

- MoB2 Molybdenum Boride Powder

- NbB2 Niobium Boride Powder

- Ni2B Nickel Boride Powder

- WB2 Tungsten Boride Powder

- MoB Molybdenum Boride powder

- WB Tungsten Boride powder

- FeB Iron Boride powder

- Metal Alloy Powders

- High purity powders

- Max materials

CrB2 Chromium Boride Powder

Haixin is one of the leading and professional CrB2 chromium boride powder manufacturers in China. Providing you with good after-sales service and quick delivery, we warmly welcome you to high quality CrB2 chromium boride powder at the most competitive price with us.

Send Inquiry

Product Description

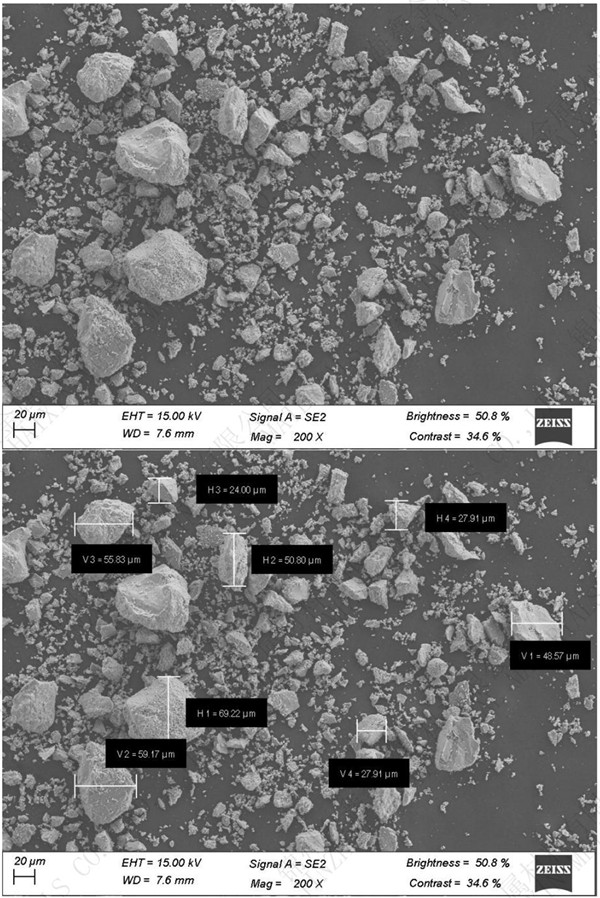

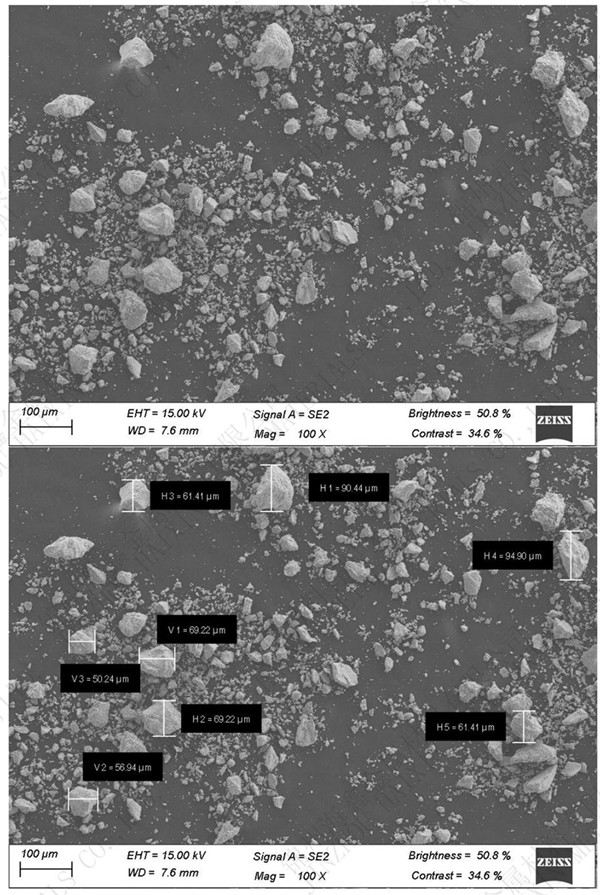

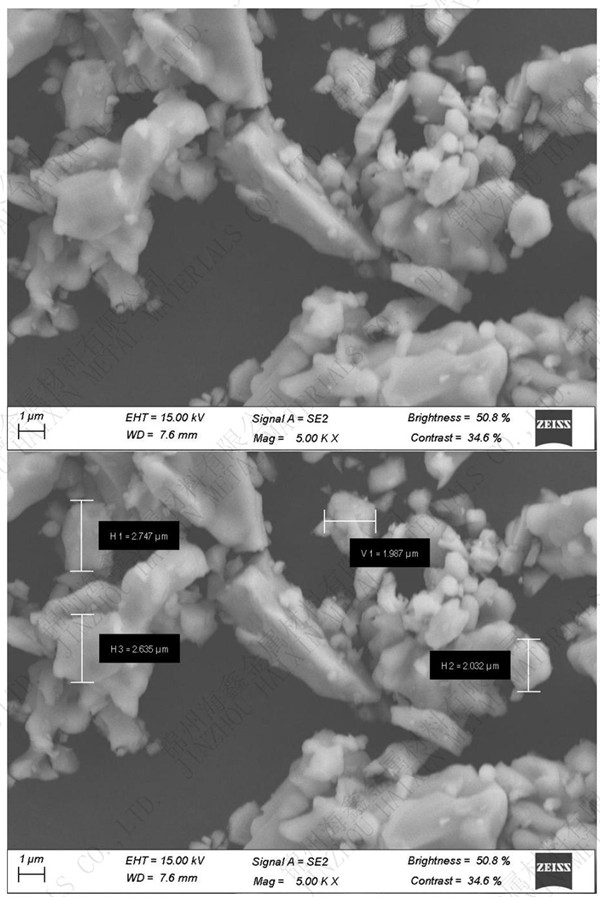

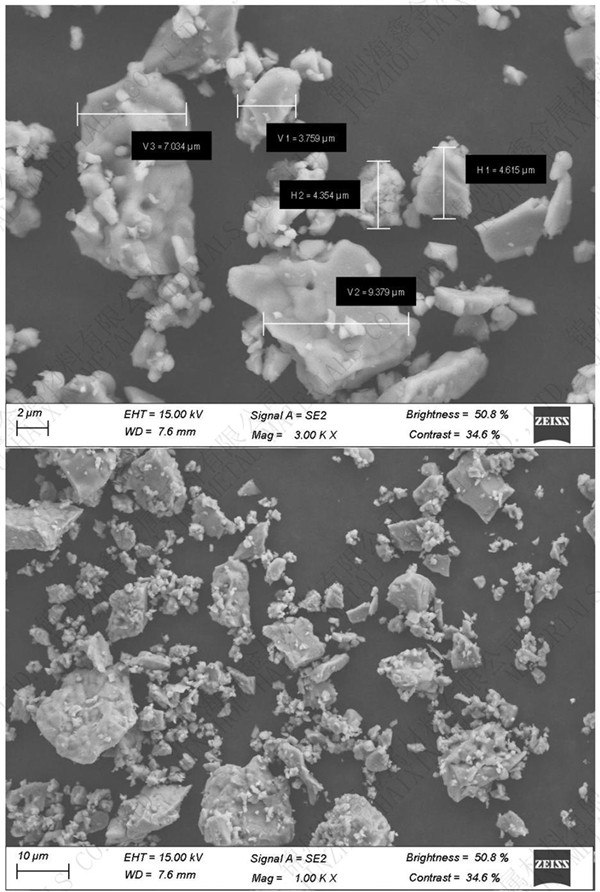

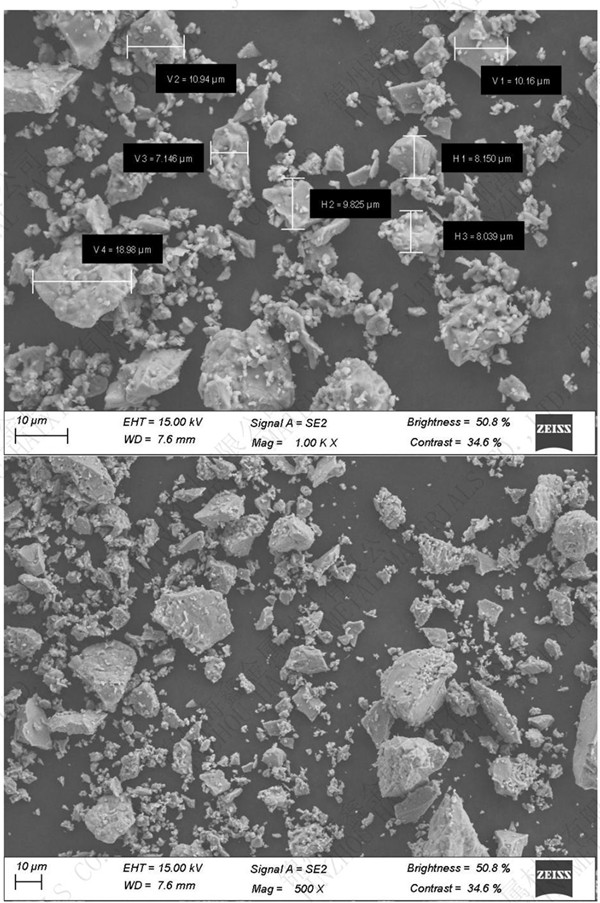

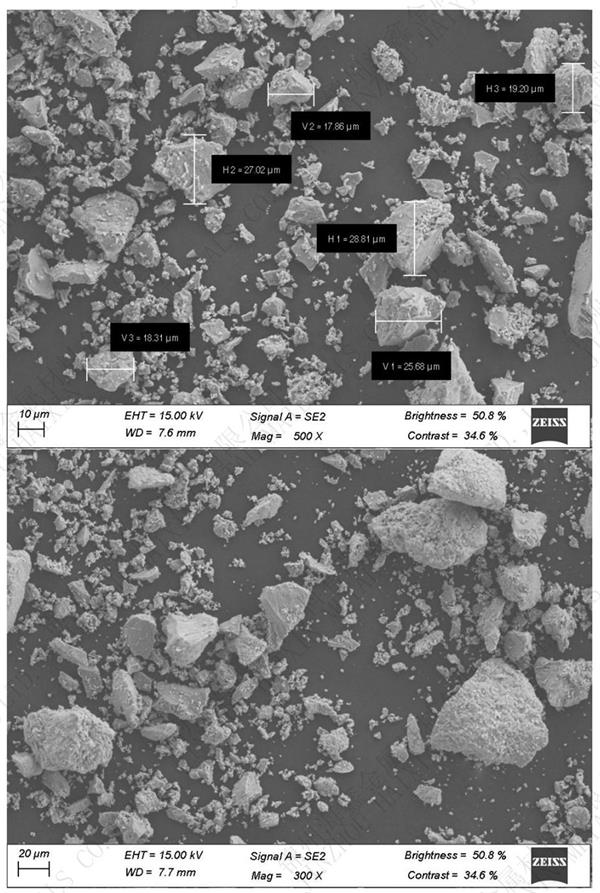

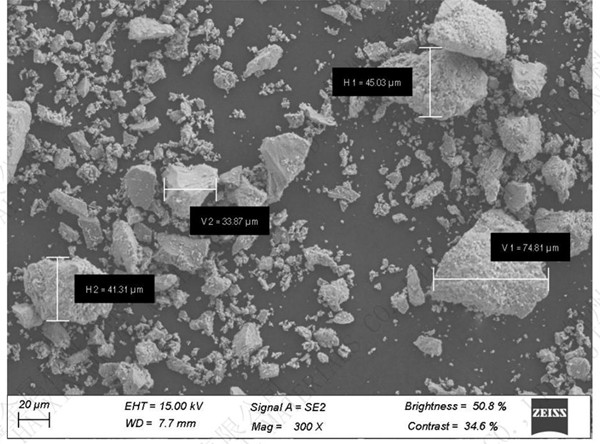

CrB2 Chromium Boride Powder

Product Name: chromium diboride

The molecular formula of chromium diboride: b2cr

Molecular weight: 73.62

English Name: chromium boride (CrB2) EINECS: 234-499-3

Density: 5.15 English alias: chromium diboride; monochromium diboride

Flash point: melting point: 1550oc

It is used for the manufacture of high temperature electric conductor and alloy ceramics.

Chromium diboride (CRB_ 2) The coating has high melting point, high hardness, high wear resistance and corrosion resistance. In addition, it has good chemical inertia and is not easy to bond with metal. As a hard protective coating, it is expected to meet these special chip processing requirements. This paper is mainly based on the domestic and foreign CRB_ The research progress and development trend of hard coatings are focused on CRB deposition by composite PVD technology_ The preparation, structure and properties of the coating were studied. The results have important scientific significance and application value. Firstly, CRB was deposited by high power pulsed magnetron sputtering (hipims)_ The composition, phase structure and mechanical properties of the coating were characterized. The friction and wear behavior of the coating in different test environments (dry friction, distilled water and sea water) were studied. The results show that: CRB_ The coating shows (101) preferred orientation, and the main phase structure is CRB_ The atomic ratio of B / Cr is 1.76, the hardness and elastic modulus are 26.9 ± 1.0 GPA and 306.7 ± 6.0 GPA, respectively. The friction coefficients of the coating in dry friction, distilled water and seawater are 0.75, 0.26 and 0.22, respectively. The friction coefficient of the coating in distilled water and sea water environment is significantly reduced due to the boundary lubrication of distilled water and sea water. The friction and wear mechanism of the coating in dry friction and distilled water environment is abrasive wear, while in seawater environment, the friction coefficient of the coating decreases obviously, It is the synergistic effect of corrosive wear and abrasive wear. Secondly, as a comparison with hipims, the CRB is obtained by DC magnetron sputtering by adjusting the target base distance_ The atomic ratio of B / Cr varies from 1.9 to 2.0 with the change of deposition temperature. XPS results show that the coating is still mainly composed of CRB_ The results show that the roughness of the coating is small and the RQ is between 1.11 nm and 1.95 nm. With the increase of deposition temperature, the diffusion ability of adsorbed atoms on the substrate surface is enhanced, and the crystallinity of the coating gradually increases, and the crystal structure changes from the mixed orientation of (101) and (001) to (001) preferred orientation; the cross-sectional morphology of the coating changes from porous fibrous structure to coarse columnar structure (about 50 nm in diameter), Finally, it transformed into a dense nano columnar structure (about 4 ~ 7 nm in diameter). With the increase of deposition temperature, the mechanical properties of the coating are improved obviously. When the deposition temperature is higher than 300 ℃, superhard CRB with hardness greater than 40 GPA can be obtained_ When the deposition temperature is 400 ℃, the hardness of the coating is as high as 50.7 ± 2 GPa. The evolution of microstructure and mechanical properties with the deposition temperature is attributed to the (001) preferred orientation and densification of the microstructure due to the enhanced diffusion of the deposition atoms. Finally, CRBs with (101) and (001) preferred orientations are also studied_ The thermal stability of the coating was tested, and the CRB substrate and CRB at different deposition temperatures were tested_ The basic electrochemical properties of 2 coating in 3.5 wt.% NaCl solution were investigated. The results show that: (101) preferred orientation of CRB_ A new phase was formed at 1000 ℃, and (001) preferred orientation of CRB_ The results show that the (101) - oriented CRB coating exhibits higher high temperature stability due to the (101) preferred orientation of CRB_ The results show that the CRB coating has higher surface energy and lattice distortion energy than CRB_ The corrosion potential of crb-2 coating was higher than that of cemented carbide, but the corrosion current density decreased by nearly two orders of magnitude_ 2 coating can effectively protect cemented carbide.